Facts

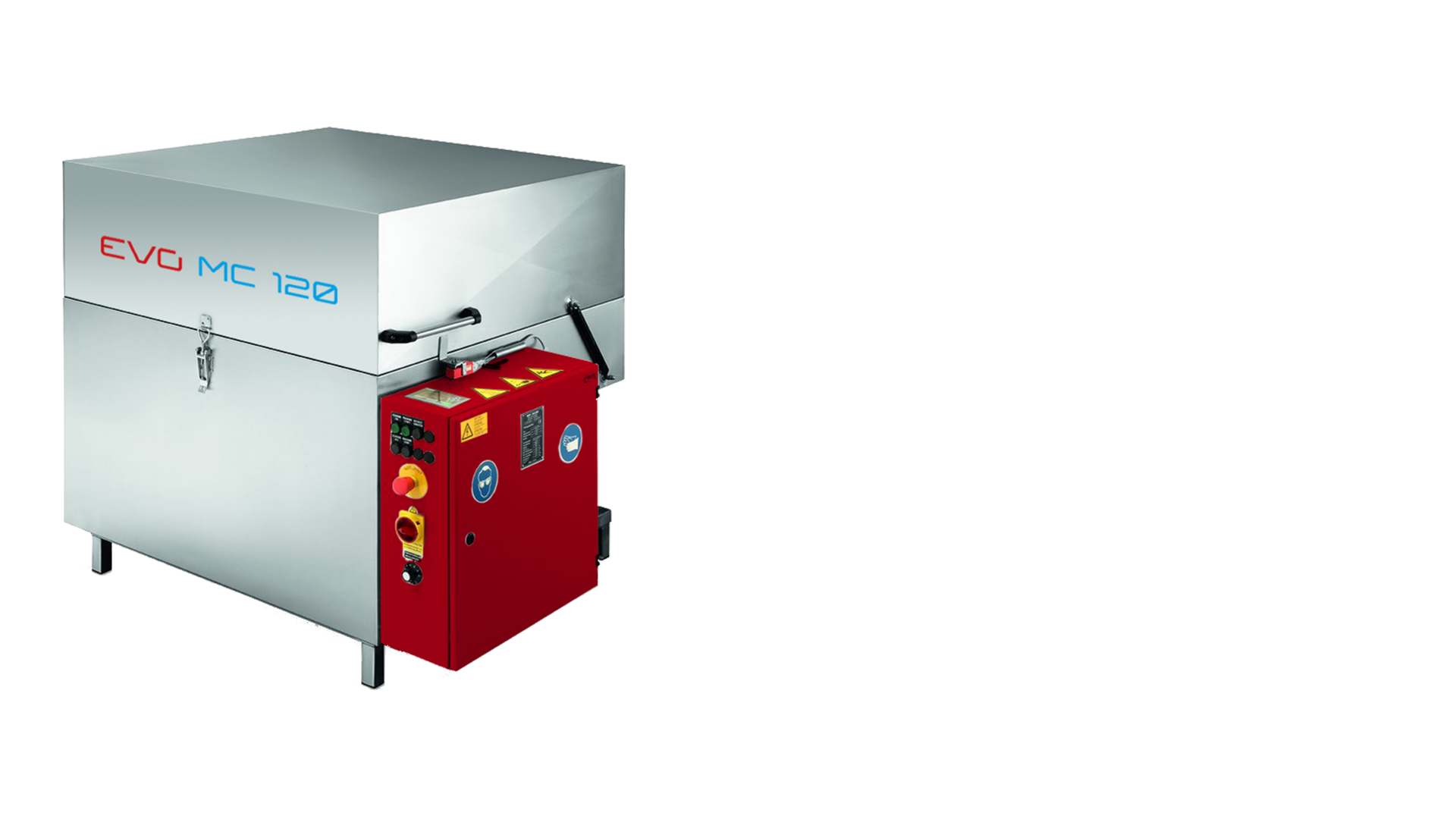

- Aqueous-based spray cleaning system

- Workstation with vertically rotating mesh basket

- Simple operation

- Space-saving

- Environmentally friendly

- Robust construction

- Reliable and durable

- low procurement and operating costs

Equipment features

- Holder for 8 or 13 solder frames EVO MC 80 / 100

- Steam extraction

- Level control

- System insulation

- All components in contact with media are made of stainless steel

- Vertically rotating mesh basket

- Motor-driven cleaning basket

- High load capacity (max. 350 kg payload)

- Siemens Logo Control / Display Logo TD

- Highly efficient, powerful Grundfos pump IE3/IE4

- Dry run protection

- Tank cover

Options

- Fine filter in the pressure line, mounted after the washing pump

- Circulating air drying system with side channel compressor and air heater

- Additional rinsing stage on discard, with drain control

Technical data

Main dimensions without additional equipment

| Technical data |

|

|

|

|

Mesh basket round

|

800 mm

|

1.000 mm

|

1.200 mm

|

|

usable height

|

450 mm

|

500 mm

|

700 mm

|

|

Width

|

1,120 mm

|

1,320 mm

|

1,520 mm

|

|

Depth

|

920 mm

|

1,120 mm

|

1,320 mm

|

|

Hight closed

|

1,000 mm

|

1,200 mm

|

1,400 mm

|

|

Load capacity

|

200 kg

|

250 kg

|

350 kg

|

|

Tank capacity

|

135 l

|

300 l

|

430 l

|

|

Peak pressure at the nozzle

|

3.0 bar

|

3.5 bar

|

3.5 bar

|

|

Circulation capacity

|

4.8 m³/h

|

12 m³/h

|

12 m³/h

|

|

Pumpmotor

|

0.85 kW

|

2.2 kW

|

2.2 kW

|

|

Electric heating power

|

4.5 kW

|

6.0 kW

|

9.0 kW

|

|

Electrical connected load

|

6.0 kW

|

8.5 kW

|

11.5 kW

|

|

Maximum power consumption

|

10.0 A

|

14.5 A

|

20.5 A

|

|

Treatment temperature infinitely variable

|

0–85 °C |

0–85 °C |

0–85 °C |

|

Tank heating time

|

approx. 1.5 hours

|

approx. 2 hours

|

approx. 2 hours |