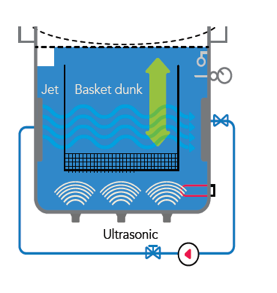

The switchable ultrasonic generators with 40 kHz and 132 kHz offer the possibility of a powerful and gentle ultrasonic cleaning for e.g. assemblies with low stand-off and wafers.

EVO SONIC ultrasonic cleaning systems set new standards in system design. Well thought-out details in the area of the guidance of the cleaning medium, agitation and process control ensure a flexible and energy-efficient process sequence in line with requirements.

Cleaning procedures

Processes that can be flexibly designed lead to optimum cleaning results.

|

Cleaning module with ultrasonic agitation |

|

Treatment module with unique SonicJet technology – combined performance of ultrasonic cleaning and pressure flooding |

|

Oscillating spray cleaning modules |

|

Washing and rinsing modules with pressure flooding |

|

Treatment module for immersion rinsing to remove particles and detergent residues |

|

Hot-air dryer with powerful fan and heater – for fast drying |

Options

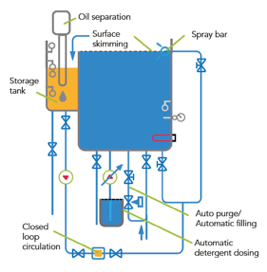

- Particle filtration

- Oil separation

- Filter blockage alarm

- Various buffer tanks

- Surface skimming

- Automatic water refill

- Automatic detergent dosage

- Automatic regulation of the detergent concentration

- Bath monitoring (pH value, conductivity)

- Oscillating washing basket

TECHNICAL data

| TECHNICAL DATA |

|

|

|

| Internal basket dimensions (mm) |

W 267 × D 367 × H 206 |

W 367 × D 567 × H 315 |

W 430 × D 610 × H 395 |

| Load weight (kg) |

10 |

26 |

39 |

| External tank dimensions (mm) |

W 549 × D 971 × H 968 |

W 653× D 1174 × H 968 |

W 723 × D 1217 × H 968 |

| Filling volume (l) |

46 |

120 |

180 |

| Heating capacity (W) |

2000 |

3000 |

5000 |

| Ultrasonic power nom./peak (W) |

600 / 1200 |

1200 / 2400 |

2400 / 4800 |

| Ultrasound frequencies (kHz) |

37 / 132 |

37 / 132 |

37 / 132 |