Capacity (euro cards 100 × 160 mm): 76 pieces with standard

upper and lower basket O500 (37 pieces) / U500 (39 pieces)

Due to their more compact design, the cleaning machines of the EVO PCB series can be optimally integrated into existing process environments.

Key features

PerfectTouchControl

Chemical-resistant glass surface of the operating and programming unit

PerfectSpeedSensor

Spray arm monitoring

Reliable cleaning performance by monitoring the spray arm speed

PerfectFlow

Media and temperature independent ultrasonic dosing volume control, reproducible cleaning quality through precise dosing of all media

PerfectPureSensor

Integrated conductivity measuring module for monitoring the final rinse phase

PerfectHepaDrying

Optimum drying results, free from unwanted particles and suspended matter from the room air

TOP feature of the EVO PCB PREMIUM

PerfectLiveControl powered by Zestron Eye or KYZEN Analyst

Digital real-time concentration measurement, live monitoring and automatic re-dosing in the media inlet. Process-related fluctuations which lead to a reduction in the concentration of the cleaning bath are compensated fully automatically. Water and cleaning concentrate are supplied in real time and ensure optimum process reliability.

TOP-Option of the EVO PCB PREMIUM

Trace & Connect

Traceability

Recording and storage of the following process data:

-

Assignment of PCBs to the washing cycle via batch number (hand scanner optional)

-

Cleaning machine (type and serial number)

-

Machine location

-

Selected cleaning programme

-

Date / time of programme start

-

Concentration of the cleaning agent (EVO PCB PREMIUM)

-

Tank temperature

-

Pump pressure

-

Conductivity measurement of the rinsing phase

-

Error messages

-

Programme Ok (Yes / No)

-

Date / time programme end

Sensors and control system expandable via CAN bus

Connectivity

-

Integration into existing company network via LAN/WAN possible (router optional)

-

Monitoring of the cleaning process / status query

-

Access to traceability log file

-

Remote diagnosis

ADDITIONAL FEATURES

- Steam vapour condenser (free of exhaust air)

- Complete stainless steel piping of the MRS module (Matthes Recycling System)

- Drawer for 4 × 5 l canister

- Sensor system for automatic basket/trolley detection

- Programme Failure Protection

- 2 redundant sensors for temperature control and monitoring

- Miele Waterproof System to protect against leakage damage

- Remote serviceable

Medium canister

PerfectSpeedSensor Spray arm monitoring

Trolley detection

Accessories

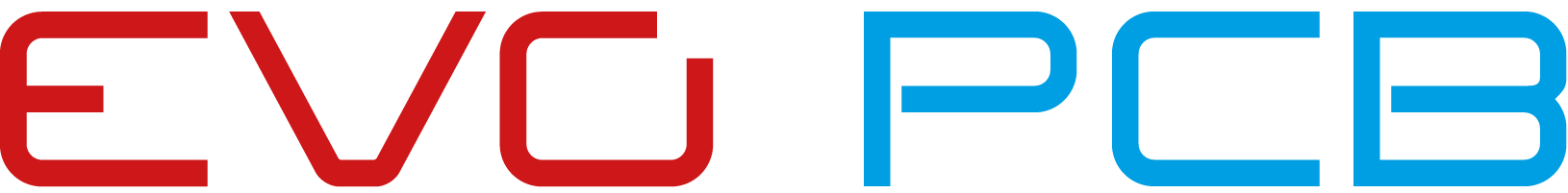

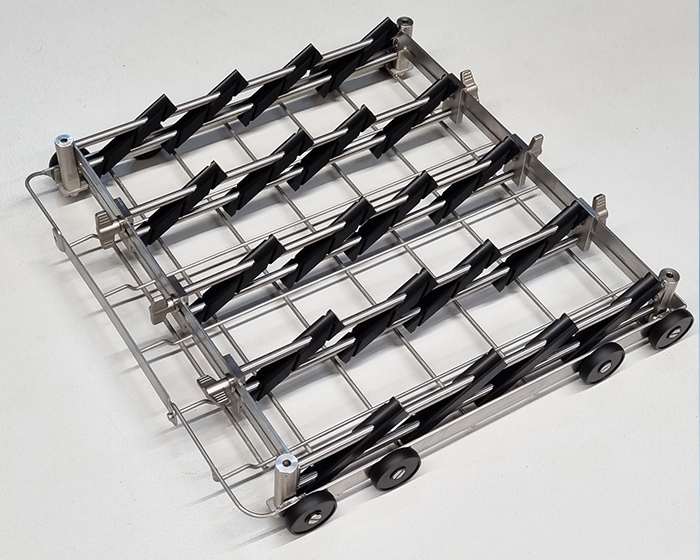

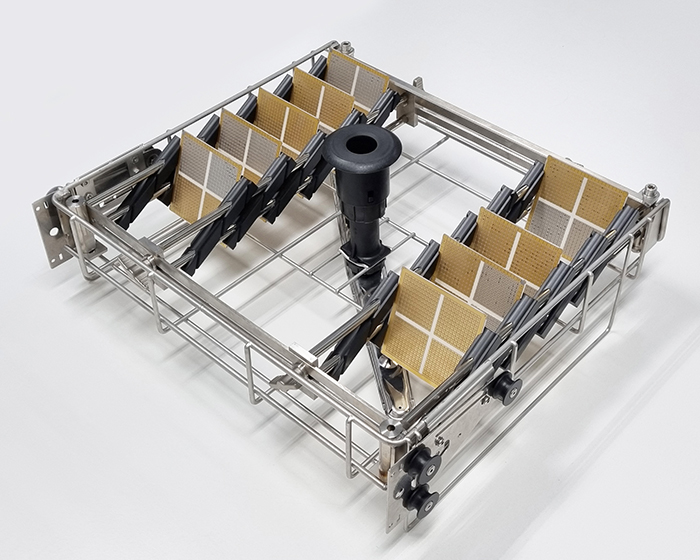

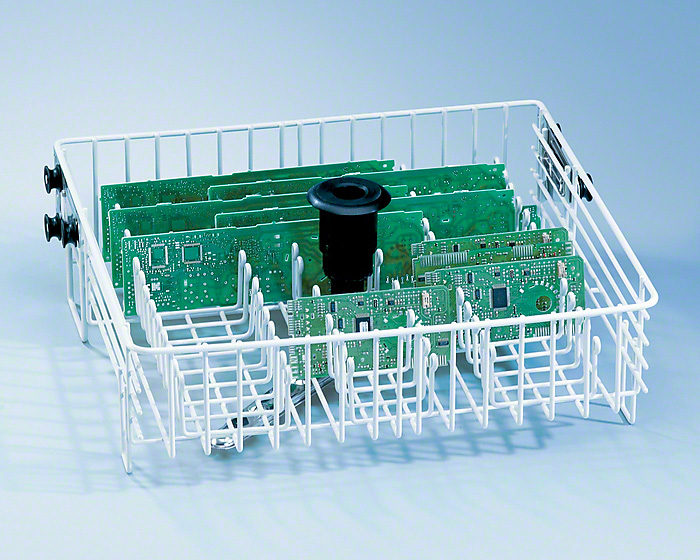

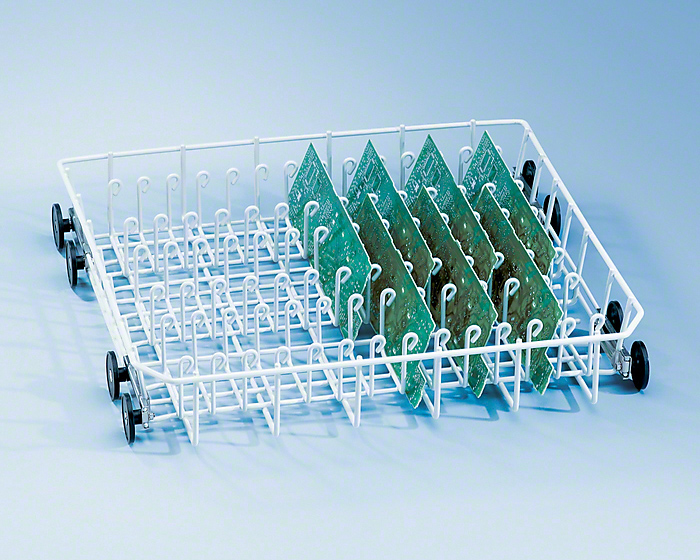

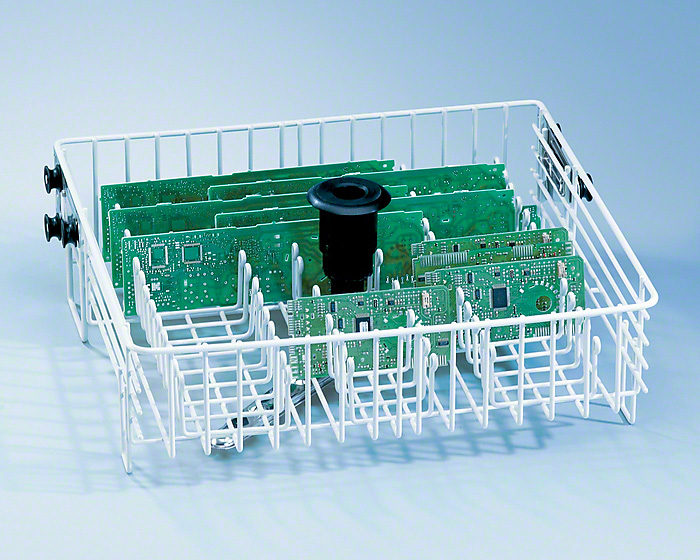

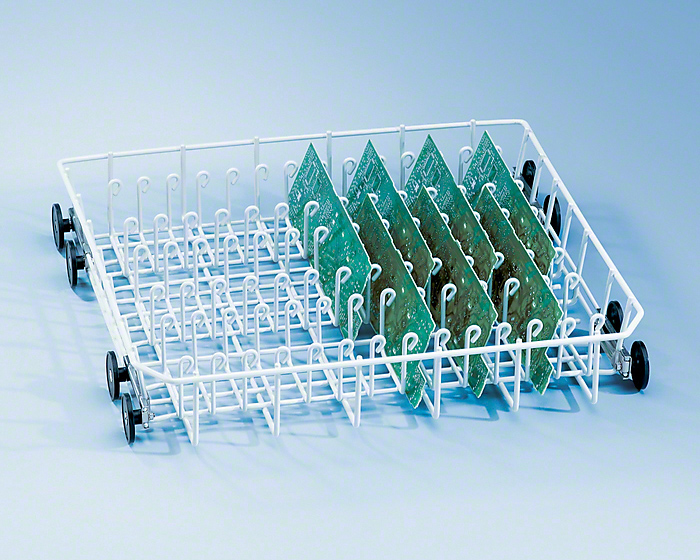

Precision-milled parts made of stainless steel and ESD conductive HDPE plastic, chemical resistant, abrasion and and cut-resistant, guide rails infinitely adjustable horizontally, PCB holder made of ESD plastic for PCBs up to 4.0 mm thickness, basket with rollers made of ESD plastic

EVO Standard basket system

Upper basket O500

Lower basket U500

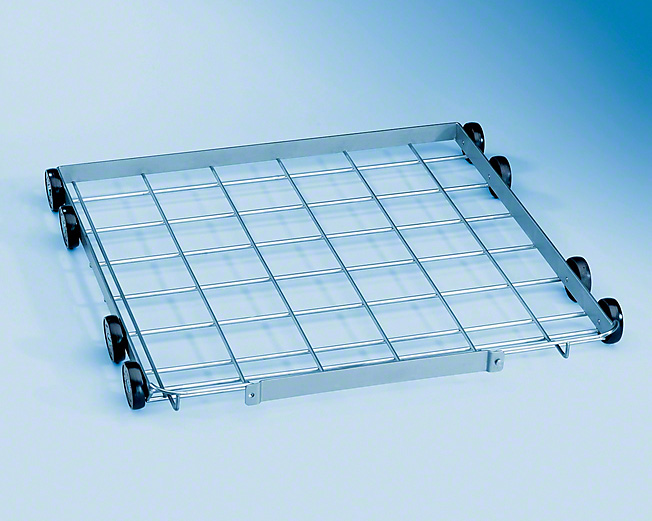

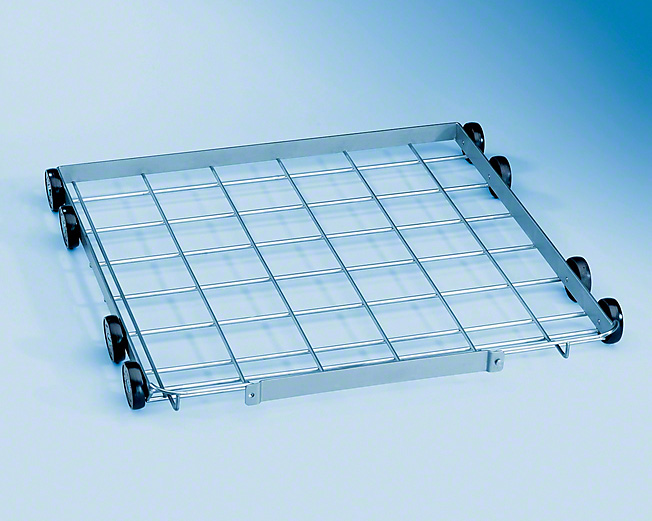

Upper basket empty O188

Lower basket empty U87

More Features

DI water cartridge

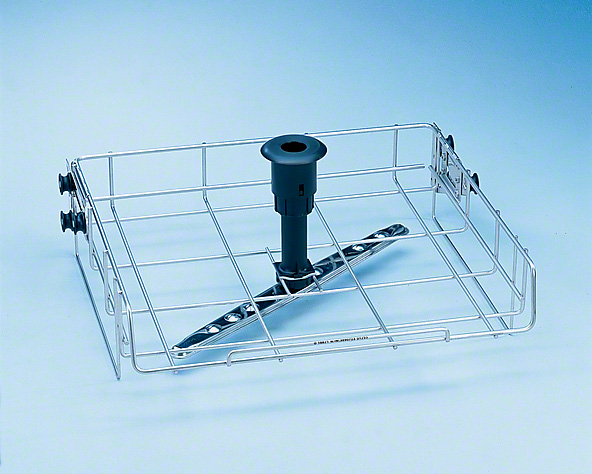

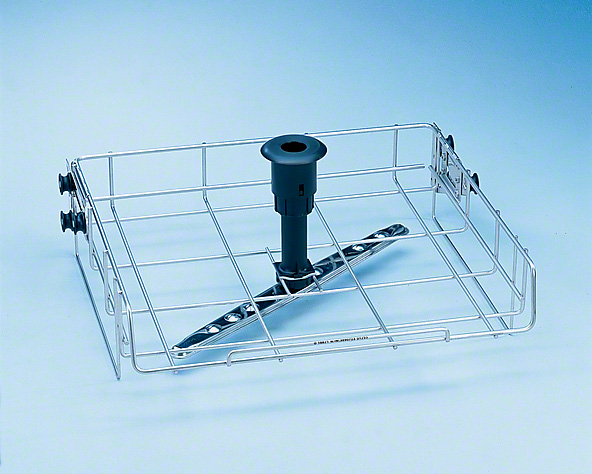

Carriage with rotating basket

Customised holders can be manufactured.

Technical Data

| Technical Data |

|

/ /

|

|

| |

Ultra-fine cleaning systems for assemblies (unassembled and assembled printed circuit boards), misprints (misprinted circuit boards) |

| Technology Matthes |

EVOLUTION |

| Cleaning capacity per process |

(euro cards 100 × 160 mm): 76 pieces with standard upper and lower basket (37 + 39 pieces) |

| Tank capacity 1 |

60 litres |

| Tank capacity 2 |

— (fresh water system for reproducible rinsing results) |

| Power supply |

3PH 400V 32A CEE 50 Hz PE/N |

| Power consumption |

4 kW |

| Control system |

Eaton SPS with 10,5“ Touch-Display / Miele Profitronic+ |

| Heat output tank 1 |

3 kW Control range 0-80 °C |

| Drying unit |

blower 0.3 kW / heating coil 2.3 kW / air capacity 55 m3/h |

| Hepa filter class |

H14 – Separation efficiency (according to DIN EN 1822) 99.995 % |

| Filter system washing tank |

coarse filter with 25µ filter cartridge / fine filter with 5µ filter cartridge |

| Supply connection 1 (Tap water) |

3/4” |

| Supply connection 2 (DI water) |

3/4” |

| Supply connection 3 (compressed air) |

5 bar 0.2 NL control pressure |

| Drain connection (rinsing medium) |

DN 50 |

| Exhaust air connection |

Steam condenser |

| Machine dimensions |

W 1.565 mm × D 735 mm × H 1.460 mm (with signal lamp 1.700 mm) |

| Installation dimensions with base tray |

W 1.990 mm × D 800 mm × H 1.462 mm (with signal lamp 1.702 mm) |

| Operating noise EN ISO 3746 |

< 65 dB(A) |

| Tare weight |

440 kg |